The brief paddling session at La Jolla, where my sister and I spread our mother's ashes, has rekindled the kayak bug in me. In spite of the back spasms, I felt pretty good. Just getting out on the water after taking three months off was very cool. Every time my back problems force a kayaking hiatus I go into some serious withdrawal symptoms. This time wasn't as bad, because I got totally wrapped up with getting ready for hunting. All the working out to get ready for hunting hasn't really helped the back. I was hoping to kill two birds with one stone, but I haven't killed anything except my back. I might need another epidural to get through deer season and winter yellowtails.

In preparation for future kayaking, I've pulled the old power distribution unit/battery box and replaced it with a new one. The new battery box uses the same Underwater Kinetics waterproof case that I used for the old one. Amazingly, even though I added another battery, I simplified things a little. I've done away with all the lights. The only time I'll ever use anything other than a headlamp is for lobster hooping. For that activity, I think that having a mast-mounted light would be essential. When I need to use the mast light, I'll just make a mast with an integral battery and come up with some sort of temporary mount.

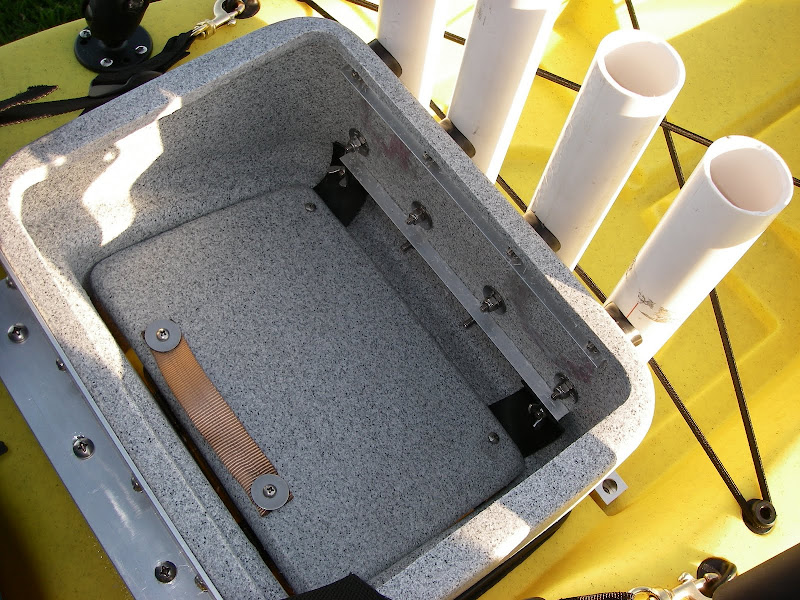

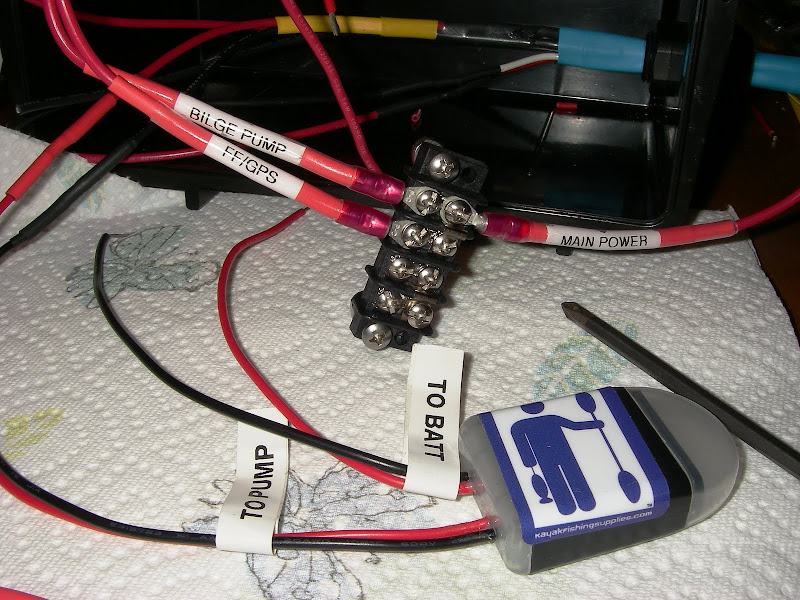

So, here are some pictures showing the construction of the new PDU.

I started out by soldering leads to the switches that I'd be using and then coating the switches in Plastisol. The Plastisol does a great job of waterproofing the switches. After receiving several coats of Plastisol and getting some time to dry, I drilled holes in the case lid and installed the switches.

I decided right from the start that I was not going to use crimped butt splices inside the case. I wanted better electrical connections and more flexibility than crimped connectors would provide. This meant more work, but the final product was worth it. This time I had my handy-dandy Pan-a-Vise, which made the soldering much easier.

I tried to make this as clean and orderly as possible. Again, all connectors had wire markers which were protected with clear heat shrink. I also got to try out the new, programmable bait tank timer from OEX. This is better than having to buy and install a new switch if the water flow needs to be tweaked a little.

As always, I stuck to the schematic when doing the assembly. I have a tendency to screw things up when I ad lib. This new PDU features two batteries and two separate circuits. The bait tank pump will run off of a 6V 12a-Hr. battery. The 12V system supplies the FF/GPS and the bilge pump. As the bilge pump is only for emergencies, I should get several days of usage from each charge of the 12V battery. This will make extended outings or mothership trips doable without having to take a charger. I've found from experience that the battery will run the pump long after I've reached the 10.2VDC low-voltage shut down point on the FF/GPS. There is no chance that just the FF/GPS will run down the battery to the point that the bilge pump can't do its job.

With this project, I tried a new assembly approach. Rather than wiring up the system and then installing the parts, I did things in a more logical order. I installed the switches and external cables and then soldered all the wires together. This method is a little more difficult and time consuming, but it made the final routing of wires much easier. The previous PDU was a pain in the butt to wire up. I had already installed the terminal block and I had to attach the connectors to it inside the box. I think I dropped those damned tiny screws a dozen times while installing each connector. This time I made up all the soldered connections and then attached the wires to the terminal block outside the box. With the mounting holes already drilled in the box, mounting the terminal board once it was all wired up was a breeze.

After all the electrical connections were made, I broke out the multi-meter to do the pre-install testing. I learned my lesson on the last PDU.....never blindly trust my own work. As Ronald Regan said; "Trust, but verify." I made sure that everything worked properly before I installed the terminal board and dressed the wiring. Better safe than sorry.

I could have dressed this out a little neater, but there just wasn't a lot of room in the PDU once the two batteries were installed. My main objective was to ensure that the lid could be opened and closed without crimping wires or pressing on any components or connectors.

The finished product is pretty nice. It sealed up well, so I don't think I'll have to add desiccant packs. All exposed metal and connector pins got a coating of Fluid Film for corrosion prevention. I am going to leave this PDU in the kayak all the time. I will just remove the batteries for charging. I don't like leaving the connectors laying, exposed in the bilge anymore. The Stealth takes on too much water for this to be a good practice. I've already seen some corrosion on the original connectors inside the hull. From now on, I'm only going to pull out the PDU if I have to remove all weight from the yak. I'll just spray the connectors with Fluid Film, plug them in and leave them in place.

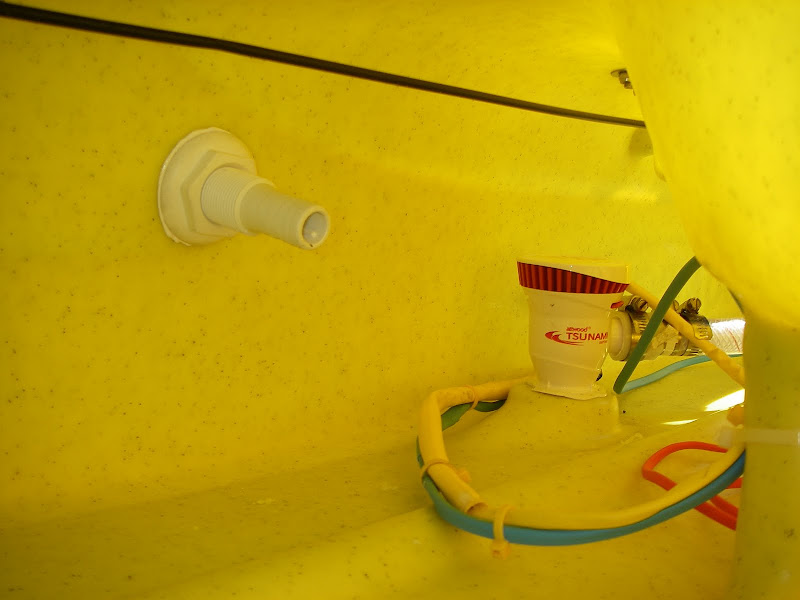

Next step is installing the bilge pump and overboard discharge line. I think I'll do that when it cools down a little.

.jpg)

.jpg)