|

| From The Overloaded Kayak Images |

As you can see from the photo, at least 12 inches of the rudder lines are exposed on each side. Not only is this a little unsightly, the lines get in the way of the hatch covers and they tend to get caught on things. I understand that Malibu is working up a fix for this; some sort of conformal plastic tube guide. That doesn't do me much good, but I will deal with it. On the subject of rudders; some will say that they aren't even necessary. I agree with this only to a point. The Stealth 14 tracks well enough without the rudder; maybe not quite as well as a Prowler Trident, but well enough for a large yak. I can say definitively that it tracks better than my old Ocean Kayak Drifter. That being said, there are many (if not all) situations where having the rudder is a distinct advantage. I don't buy the argument that the rudder installation or maintenance outweigh the benefit. Maintenance is practically nil and you only have to install it once. You will reap the benefits of using the rudder ever time you paddle. For me, with a bad back and a shoulder that seems on the verge of going south, the benefit of having a rudder is enormous. I can concentrate on maintaining a smooth, symmetrical paddle stroke, regardless of wind conditions. That alone probably adds hours to my endurance. As way of example, I spent 11 hours on the water Monday in breezy conditions. If I had to constantly correct my drift with paddle strokes, I doubt I could have lasted more than 5 or 6 hours. So enough of that. The Stealth 14 isn't a rudder-friendly design, but you can easily make it work. The rudder pedal rails went on with only a little drama. The hole pattern on the rails doesn't quite line up with the nut inserts on my Stealth. I should have checked both before drilling. I checked one and it fit, so I expected the other to fit, as well. Wrong. Not a problem. I just milled some oval holes in place of the round. I also added a third attachment point for a through-hull bolt. No way these are coming off, even if I do a lot of stomping on them in the surf. I had to attach an eyelet at the front of the footwell for a bungee pedal retention system. There is no stop on the foot pedal rails, so the pedal slide will fall out when lifting the yak onto the truck. The retention bungees were a piece of cake. I was even thinking about routing the bungee through the hull to connect the two pedals. This would allow feedback from one pedal to the other. I might do that in the future, but I wanted to keep things as simple and light as possible. The supplied rudder mount is a little long for the Stealth hull. This isn't much of a problem unless you are going to carry the kayak on a truck rack. The angle of the kayak when you lift the bow up to the rack pretty much assures that you will be resting on the rudder mount and not the hull. This isn't a huge issue. I just need to be careful when taking the kayak off the rack. I also had to cut the rudder post down to fit the mount.

|

| From The Overloaded Kayak Images |

The fish finder mount was a bit of a quandary. I've always had the FF head unit mounted on the centerline of the kayak. This has always been problematic. If it is mounted far enough forward to be out of the way, it isn't easily accessible while fishing. Mounting it closer makes it easy to operate, but it gets in the way when getting on the kayak and when trying to land a big fish. I decided to go with a cockpit rail mount this time. I always mount the kayak from the port side, so it would have to go on the starboard cockpit rail. This position makes it a little difficult to straddle the kayak, but it is the best overall position.

|

| From The Overloaded Kayak Images |

The FF head unit is mounted on a 6" RAM mount. The articulated RAM mount allows for a great deal of positioning flexibility. I can move it so that it is close enough to easily operate without having to lean forward and also rotate it completely out of the way for surf landings.

|

| From The Overloaded Kayak Images |

The transducer installation was an absolute cluster-frak from the very beginning. I started with the notion of doing a wet well transducer installation. The theory behind this is that there is no layer of Goop or 5200 to interfere with the signal. You make a little well, attach it to the hull and then set the transducer in the well. Many have tried this mounting method and it works well. I have done over a half dozen Goop/5200 installs with very good success, so why did I want to try this? I don't know. I am always looking at different options for the yak. I thought I should give this one a try. Experience told me that this was going to be a problem, but I didn't listen to the smart voices in my head. The 'try something new' voices in my head prevailed. The only smart thing that I did was to publicly make the statement that if it didn't work right the first time, I was going to rip it out and go back to the Goop.

The first obstacle to overcome is the giant skimmer transducer that came with my Lowrance LMS-527. Did I mention that the transducer is huge? Too big for the traditional wet well made from 3" or 4" PVC pipe. As the LMS-527 is no longer in production, there aren't many transducer options from Lowrance. Most of the compatible transducers are large or ungodly expensive. I almost wish I still had the Humminbird with its huge selection of cheap transducers. I would have said screw the wet mount and gone with a a thru-hull mount if they weren't so damned expensive. The thru-hull dual frequency transducer was $869. That's just crazy. That's nearly what I paid for my kayak. Cost was going to force me to stick with my current transducer; and that meant a big wet well. When the PVC pipe wouldn't work I started thinking of other materials. I had used clear Lexan for other projects and it seemed like a good bet. I bought several Lexan sheets from Lowes and commenced to make a wet well. The most difficult part was cutting the hull contour on the front and back walls. I got a contour gauge and managed to get a pretty good representation of the hull contour cut into the Lexan.

|

| From The Overloaded Kayak Images |

I reinforced the corners and edges with thin aluminum angle. I even cut a small fill port with a fill plug. As I was putting this together I realized that it was an all-or-nothing proposition. If it didn't work once it was glued into the hull, there was no real remedy.

|

| From The Overloaded Kayak Images |

I used 3M 5200 for the seal to the hull. 5200 is more flexible than Goop and you need that to maintain a good bond to the hull. I added a layer of Marine Goop over the side angle to get more mechanical strength.

|

| From The Overloaded Kayak Images |

It worked well enough on the shakedown cruise, but there wasn't a huge performance difference between the wet well and previous Goop-to-hull mounts. The second time out it dropped the kayak as I was getting it off the truck. The shock evidently cracked the Goop that was used to seal the corners. The water slowly leaked out over the course of the first few hours on the water. I probably could have Gooped all the seams again and solved the problem, but I was in no mood to do that. As soon as I got home I tore the well out. I Gooped the transducer down on a flat portion of the hull outboard of the bait tank. I don't know if it was the good Goop job or the position, but I've never had such good sonar performance. I can easily track jigs and even sibiki rigs down at least 100'. Should have just gone with that from the start. I could have saved myself quite a bit of time and effort. Damnit. I should learn which voices in my head to listen to.

After clipping in my new GTS Expedition seat I realized that it overhung the bait tank hatch. The hatch is pretty big and probably any seat would have clearance issues.

|

| From The Overloaded Kayak Images |

The answer was to cut out the existing small screw-in hatch and replace it with a larger one. after a failed attempt to mount an 8" Beckson deck plate-style hatch, I ended up using a 10" hinged hatch.

|

| From The Overloaded Kayak Images |

One of my big gripes with the X-Factor was that the rear hatch was so close to the water line it was unsafe to open in choppy conditions. The Stealth 14 design has addressed this problem by raising the lower lip of the hatch by about an inch. In spite of this, I wanted a little bit more margin when accessing the rear hatch. When I had the X, I had come up with an idea to solve with problem and give me a little extra storage space. I really wanted to do away with the milk crate in the tank well and move that storage volume to the rear hatch. My solution was to convert a drop-in bait tank to a hatch extension/storage box. The idea was to bolt the tank directly to the hull. The plan went a little astray when my kayak arrived. I meant to have the factory install only the forward and center hatches. I wanted to cut out the rear to get the closest fit with the drop-in tank. Well, I didn't tell them and the kayak arrived with all the hatches already installed. Bummer. The tank doesn't fit close enough to the hatch rim to allow through-bolts to be used. I was forced to attach 1" aluminum angle to the forward and aft sides of the tank and bolt through this to mounts on the hull.

|

| From The Overloaded Kayak Images |

I bolted some aluminum box beam to the hull and then used 1/4-20 well nuts as the attachment points. It took a bit of work, but it is very light and seems like it is bomb-proof. I cut the bottom out of the tank, flipped it over and reattached with straps.

|

| From The Overloaded Kayak Images |

A couple of pieces of aluminum angle on the sides act as stops, to prevent the inner hatch from falling through. This allows me to put the battery box/PDU underneath and still use the top part of the tank for storage.

|

| From The Overloaded Kayak Images |

To complete the hatch extension/storage box I added some rod holders. To attach these I had to remove the threaded fittings that were installed in the tank. I cut these out with a Dremmel tool, cut discs out of a spare piece of hull and then plastic welded the discs in place. With the rod holders in place you can hardly see the weld marks.

|

| From The Overloaded Kayak Images |

Adding the rod holders seemed to double the weight of the whole assembly. I might replace the PVC tubes that I am currently using with a lighter plastic type. I might just eliminate them altogether. I'm going to give it a few more trips before I decide.

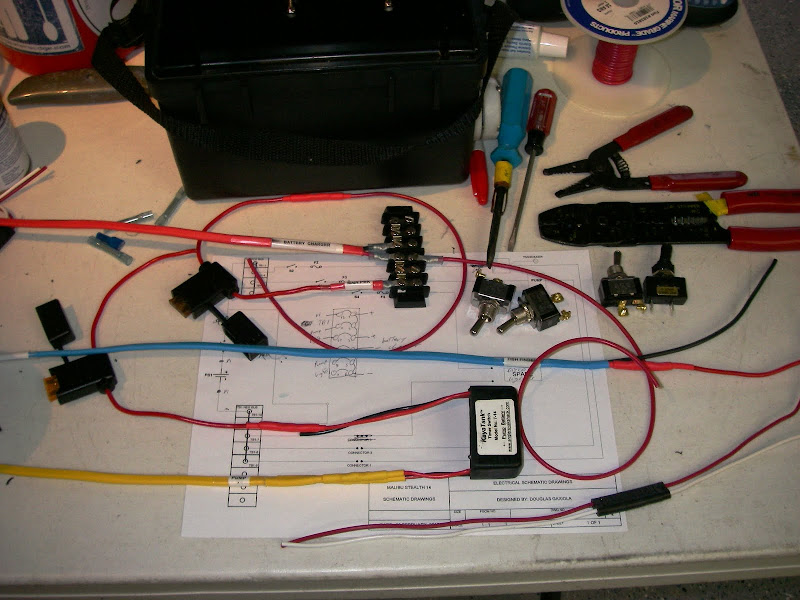

The electrical system was fairly straight-forward, if somewhat time consuming to put together. I used nearly the same setup as I had on the X-Factor. I just simplified things a little on the schematic and started wiring.

|

| From The Overloaded Kayak Images |

I tried to be as methodical as possible as I started assembly.

|

| From The Overloaded Kayak Images |

I used wire markers for everything.

|

| From The Overloaded Kayak Images |

I didn't solder most of the wire connections this time. I had access to plenty of marine-grade butt connectors with adhesive heat shrink. These are a little chunkier than soldered splices, but take much less time.

|

| From The Overloaded Kayak Images |

Here is the finished product.

|

| From The Overloaded Kayak Images |

All the wiring was dressed as neatly as possible for such a small unit. The 'Curious George' LED lights on the front of the battery box/PDU are meant to light up the hull from within.

|

| From The Overloaded Kayak Images |

This is mostly for show, as they will kill my battery life. Still; it is very cool to see the entire hull glow from within. I can use that when I'm hooping for lobster in the bay. I won't need the bait tank pump, so I won't have to worry about battery consumption. It should make me a little more visible than a single white lite on a pole.

Rod holders were the last step. I had intended to use all RAM tubes instead of flush mounts. The rods sit too low in the flush mounts and the reels get splashed quite a bit. The RAM tubes get the reels out of the splash zone. My only concern with the RAM tubes is that they are heavier than other rod holders. I've used the aluminum tubes in the past. They were heavy enough and I didn't even want to think about how much the stainless steel tubes weighed. Fortunately, OEX now carries the new composite RAM tubes. These are much lighter than the aluminum tubes and they have a flared lip and leash attachment points.

|

| From The Overloaded Kayak Images |

Now, after having spent over forty hours on the water fishing with them, I realize that they are not perfect. They just don't grip the ball as well as the aluminum rod holders. I even tried scuffing the inner surface of the clamp with some coarse-grit sandpaper to no avail. My last time out I couldn't keep them in position. After fighting a fish for a while, I noticed that two of the rods holders had slipped down and the reels were underwater. Now that's some bad juju. The next step is to grind some shallow groves in the clamp face with a Dremmel tool. If that doesn't work I'm replacing them with the aluminum tubes. It sucks that I just sold the three old aluminum tubes that I had left over from my Prowler.

Here is the end product

|

| From The Overloaded Kayak Images |

Next post I'll give my impressions of how she paddles.

No name for her yet, but I'll come up with one soon.

.jpg)

.jpg)

Awesome job man! I just sold me Big Game Prowler 3 days ago and am on the hunt for a stealth 14. I have an idea for the transducer wet well and would appreciate your thoughts, i got the idea after reading what you tried to do and then ended up doing. I made a drawing, but i am in no way an engineer or an artist, haha.

ReplyDeleteTake the "IN" hose to the bait tank and "T" it with a smaller hose that goes to a wet well enclosure that holds the Transducer. use the same size hose to from the wet well and "T" that to the drain hose that comes off of the Bait Tank and exits the kayak. Question is, if you have a fully enclosed clear lexan box that is inside the hull, Will the transducer work properly going through the lexan and then through the hull? The only benefit of doing this way would be to obtain instant accurate water temperature without hanging off the side of the kayak or going through a scupper.

I've got tons of ideas to do to the stealth and i really like some of yours and i may use some of them. I would really like to see some night pics of the kayak with the inside hull lights, that is up there on the cool factor!

Terrill

ReplyDeleteI would caution against connecting a wet transducer well to any overboard intake or discharge line. There is no reason to do so. A static wet well helps provide a better acoustic transmission medium than Goop or some other sealant. It provides the best acoustic performance of any transducer installation other than one where the transducer is outside the hull and in the water. The wet well does not need to be supplied with sea water to provide this function. Making a completely enclosed wet well and then attaching that to the hull will likely yield worse performance than if you had Gooped it directly to the hull. The only reason to connect the wet well to an intake line would be to get better temperature readings. Think long and hard before doing that. You wouldn't get much circulation in the line in such an arrangement, so the temperature of the water in the wet well would probably still not accurately track the actual water temperature. Sure, it might be a little closer than a static (sealed) wet well, but it will still be off by some margin and it will not respond quickly to actual surface temperature changes. For this dubious gain in performance you add a significant risk. Unless you plan on using some sort of mechanical fastener, like bolts, to hold the transducer well to the hull, there is a high probability that it will fail at some point. There are no standard adhesives that will provide a good bond with the linear polyethylene of the kayak hull. You can get a specialized adhesive that will bond to LPE, but even that might fail. The kayak hull flexes and most transducer wells are rigid. Even with a good bond to the hull, the flexing of the hull might break the seal. Given that risk, it would not be wise to have a seawater intake line connected to your transducer well. If the seal to the hull cracked, the pump would rapidly fill your kayak with water. Slightly more accurate temperature readings don't justify the risk. As you might notice in a later post, my transducer well failed after I had dropped the bow of my kayak twice. The seems between the rigid Lexan panels failed due to shock or torque caused by dropping the kayak. If you really need accurate temperature readings, then just buy a digital instant read thermometer from a chef's supply store. They only cost about $15 and will give reasonably accurate readings. Even if not dead on accurate, they will show temperature changes; and that is what you're looking for anyways.

That clear lexan transducer well was a good concept, but it turned out to be a major failure. Look at the ABS pipe-style transducer wells in this topic on Big Water's Edge:

http://www.bigwatersedge.com/bwevb/showthread.php?t=6508&highlight=transducer

I would have gone this route if I had a smaller transducer. Unfortunately, the transducer for my Lowrance FF/GPS is about the size of a SUP and it wouldn't fit into this size pipe.

I never got anybody to take a picture of the internal lighting while I was on the water. I still have that old battery box, so I could put it in my kayak some night and light it up for a picture.